Developed through extensive research, Pure-Cut® and Pure-Cut®+ bring the patented process of cooling and lubrication with supercritical carbon dioxide to applications around the world.

Manufacturing leaders and engineers looking for a competitive advantage need better technology that doesn’t require massive machine tool overhauls. With Pure-Cut, companies get supercritical carbon dioxide as a machining coolant and vehicle to deliver dry and enhanced lubrication to a cutting zone for applications demanding high lubrication and high cooling, and for much faster material removal and longer tool life.

Fusion Coolant Systems is a rapidly expanding company, with Pure-Cut technology spreading across the globe. Some of the largest manufactures in the aerospace, medical, automotive and other industries are realizing the performance and sustainability benefits Pure-Cut offers, and are easily implementing the technology in their plants.

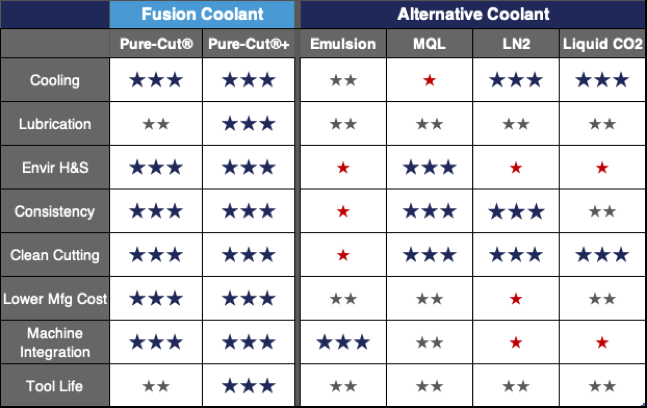

Compelling results have shown that our inventive process offers a multitude of cost-saving benefits for less operating capital than conventional cutting fluids. Our Pure-Cut and Pure-Cut+ system has lubrication and cooling properties that significantly outperform oil-in-air MQL systems, emulsions, synthetics, and straight oils. We create measurable results for aerospace, bio-medical, automotive and heavy equipment manufacturing applications that were previously considered out of reach for MQL technology.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.