Fusion’s Pure-Cut® system revolutionizes titanium CNC machining by addressing heat management, tool longevity, and surface quality challenges. Advanced sCO₂ cooling ensures cleaner cuts, extended tool life, and unmatched machining precision without the drawbacks of traditional coolants.

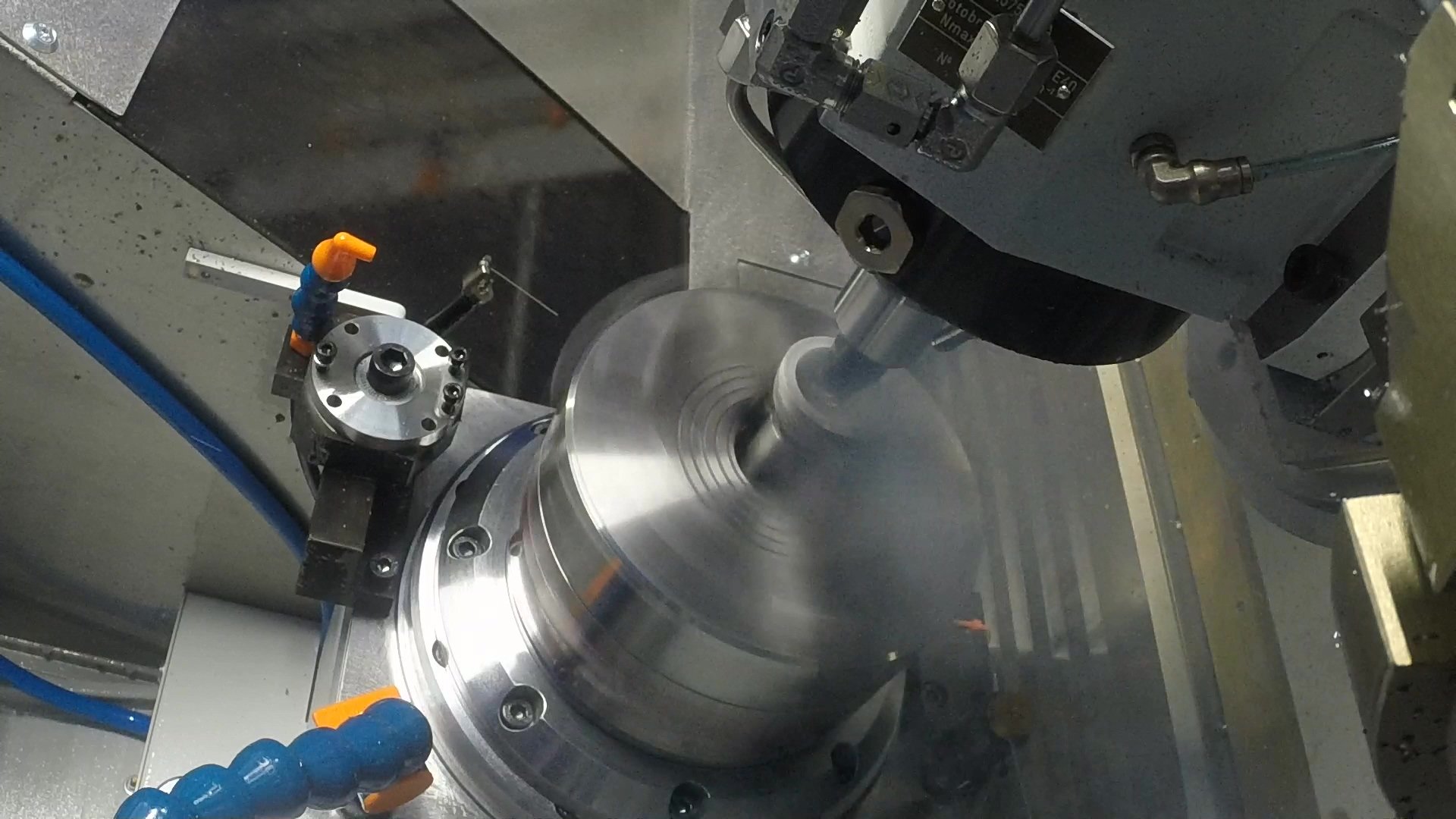

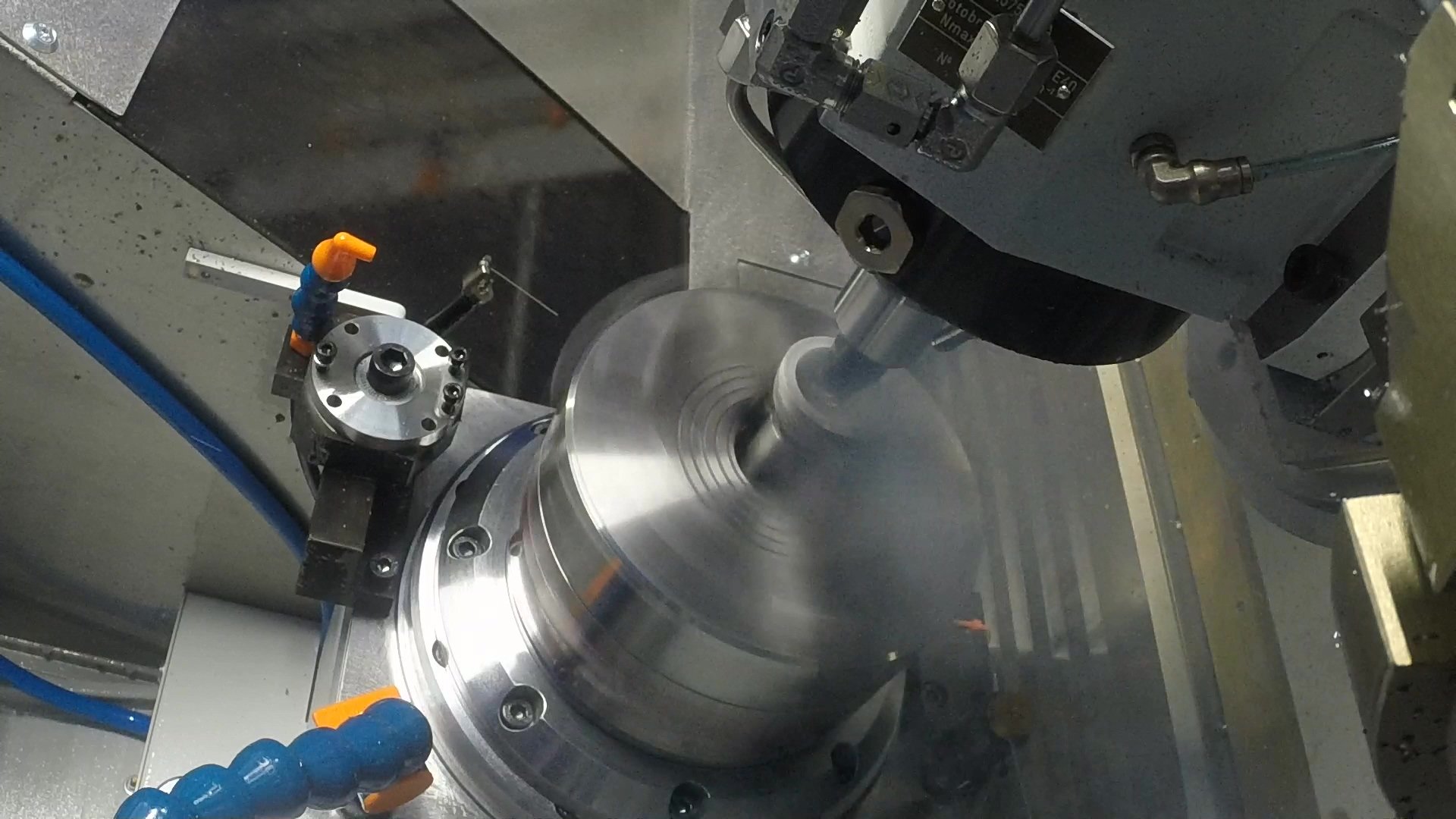

This medical application shows Pure-Cut® using ZERO oil for 100% clean machining.

Pure-Cut® with no oil sees similar or better results than traditional cutting fluids, with the added bonus of clean machining.

In this application, Pure-Cut® was 20% faster with 20% longer tool life.

We understand the challenges of investing in new technology in the titanium CNC machining space, which is why we have a no-upfront-capital-required option. We're so confident that Pure-Cut® will deliver powerful manufacturing improvements for your titanium medical implant production, our risk-free contracts will get you access to cutting-edge machining capabilities without the capital hurdle.

Pure-Cut® revolutionizes the machining of titanium components by eliminating the need for extensive downstream cleaning processes. Our advanced coolant technology ensures that machining operations are conducted with exceptional cleanliness and precision right from the start. By reducing residue and contaminants during the cutting process, Pure-Cut® minimizes post-machining cleaning efforts significantly. This not only saves valuable time but also enhances operational efficiency and ensures that medical components meet stringent quality standards without compromise. With Pure-Cut®, manufacturers can streamline their production workflows, achieve superior surface finishes, and deliver flawless titanium components reliably and efficiently.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.