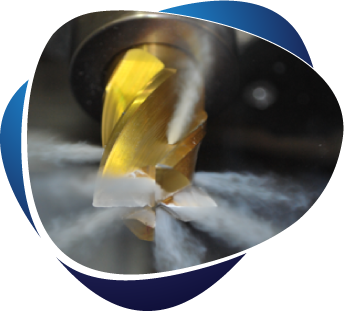

Pure-Cut® is a next-generation cooling and lubrication system that uses supercritical CO₂ (scCO₂) technology to transform automotive machining. Unlike traditional coolants, Pure-Cut® requires no oil, reducing waste, downtime, and environmental impact.

Run your CNC machines faster with the help of Pure-Cut®'s revolutionary cooling and lubricating capabilities.

Increase the longevity of your cutting tools and reduce the need for frequent replacements, lowering overall tooling costs.

Reduce downtime and improve machining efficiency by minimizing burrs and defects.

At Fusion Coolant Systems, we understand the challenges of adopting new technologies. That's why we offer a no-upfront-capital-required option for implementing Pure-Cut®. You can access state-of-the-art CNC machining technology and improve your operations without the financial strain of purchasing equipment upfront. Our flexible hardware-as-a-service model allows you to pay for the system on a subscription basis while benefiting from the increased profitability and efficiency that Pure-Cut® brings.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.