See Fusion Coolant Systems customers working to cut faster, longer, and safer.

Product:Pure-Cut®+

Material Shown: Cast Iron

Drilling with Pure-Cut+ at the DMG Mori innovation days in Chicago, 2019.

Product:Pure-Cut+

Material Shown: Ti-64

Shown is Fusion’s Dual Cool technology. The supercritical carbon dioxide goes through the tool in this application is applied directly to the cutting edge.

Product:Pure-Cut+

Material Shown: Vanadium Steel

The productivity and tool life gains when drilling in Vanadium steel are undeniable. This study found up to 5x tool life gains.

Product:Pure-Cut+

Material Shown: Ti-64

Fusion’s Dual Cool technology is shown in this example. The Supercritical CO2 goes through the tool in this application and is applied directly to the cutting edge.

Product: Pure-Cut+

Material Shown: Ti-64

Pure-Cut+ can be used on a variety of different applications and tools. Pure-Cut can go through the tool, the tool holder, or through an external nozzle if needed.

Product: Pure-Cut®

Material Shown: Titanium

This medical application shows Pure-Cut using ZERO oil for 100% clean machining. Pure-Cut with no oil sees similar or better results than traditional cutting fluids, with the added bonus of clean machining. In this application, Pure-Cut was 20% faster with 20% longer tool life.

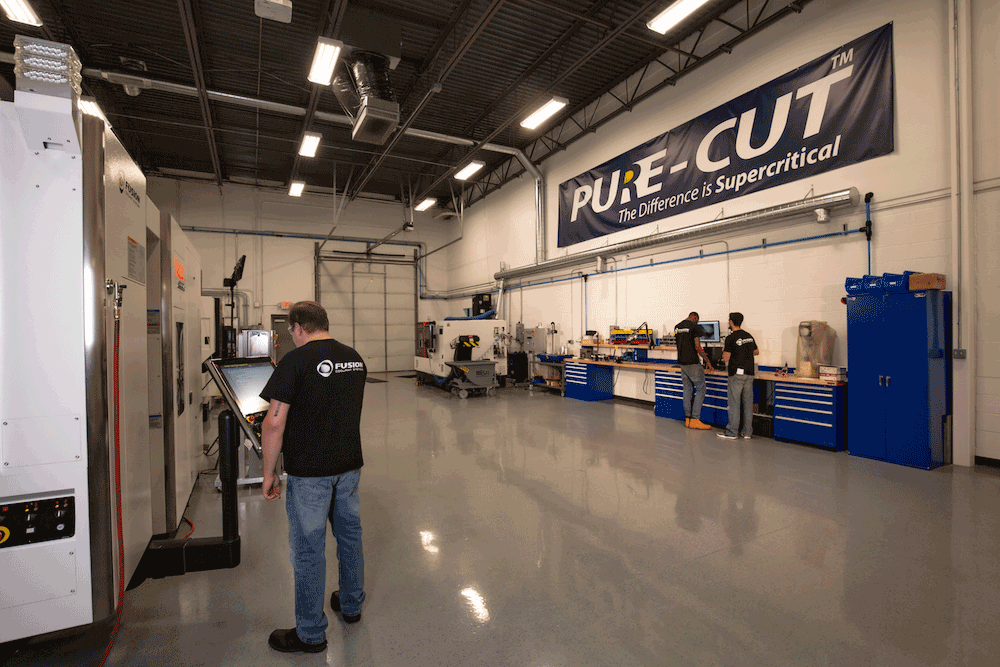

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.