Pure-Cut® revolutionizes the machining of PEEK and UHMWPE plastics by delivering unrivaled precision. Our advanced technology guarantees 95% burr-free results, setting a new standard for excellence in medical manufacturing.

We guarantee 95% burr-free plastic medical implants and will help you reach 100%.

We guarantee up to 50% reduction in machining cycles for PEEK and UHMWPE medical implant machining.

Get up and running with Pure-Cut® in as little as 6 weeks with no up-front capital required.

We understand the challenges of investing in new technology in the medical machining space, which is why we have a no-upfront-capital-required option. We're so confident that Pure-Cut will deliver powerful manufacturing improvements for your plastic medical implant production, our risk-free contracts will get you access to cutting-edge machining capabilities without the capital hurdle.

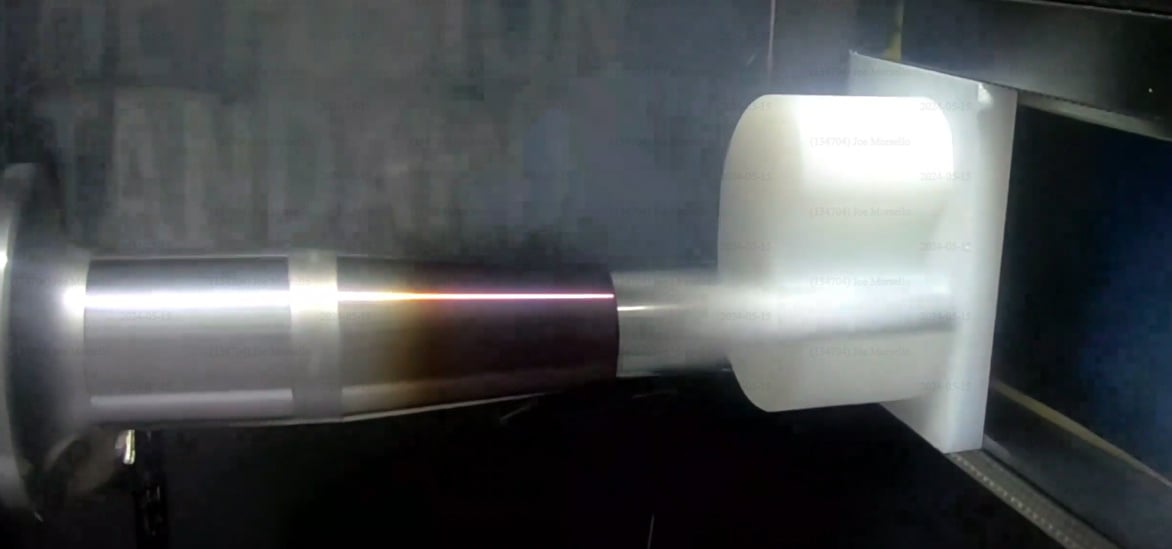

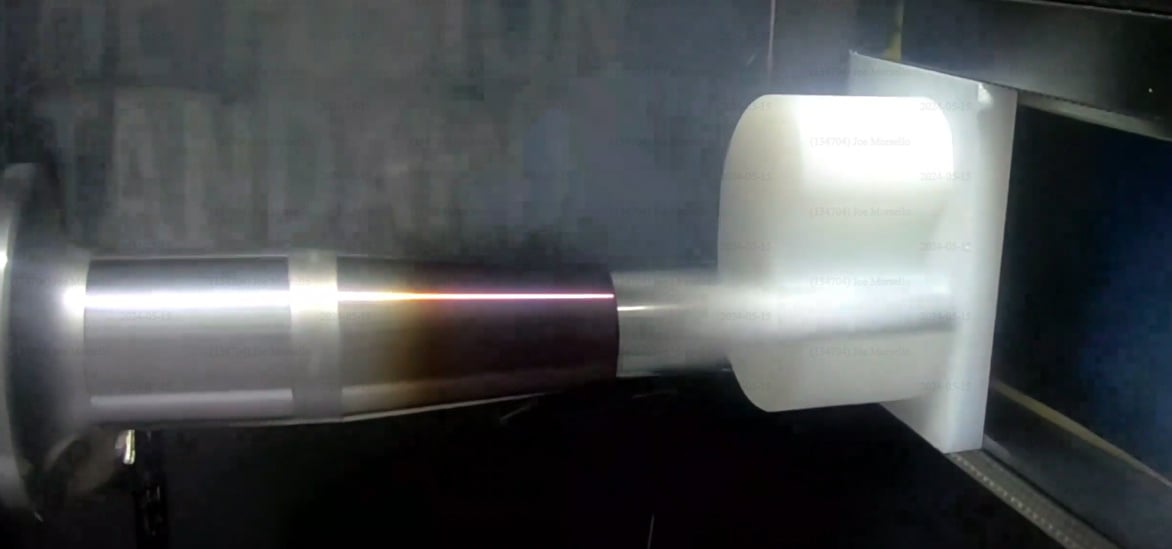

PEEK (Polyetheretherketone) has emerged as a preferred material for various medical implants due to its biocompatibility, mechanical strength, and radiolucency. Common applications include spinal implants, dental implants, cranial plates, and orthopedic joint replacements. Precision machining PEEK components with the help of Pure-Cut® is crucial to ensure optimal fit, longevity, and patient safety.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.