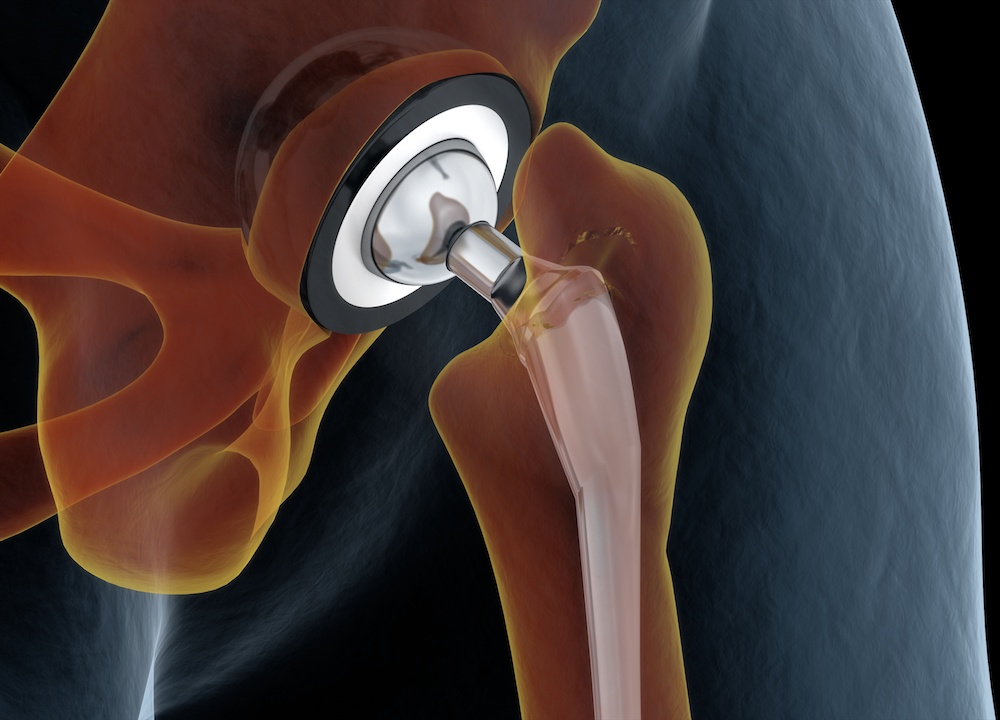

Whether you're looking to improve process capability, increase production rates, or achieve contaminant-free machining, we're so confident in Pure-Cut® technology, that we guarantee improvements in the CNC medical device machining metrics you care about.

Achieve pure, contaminant-free machining with superior machining cleanliness vs. flood coolants.

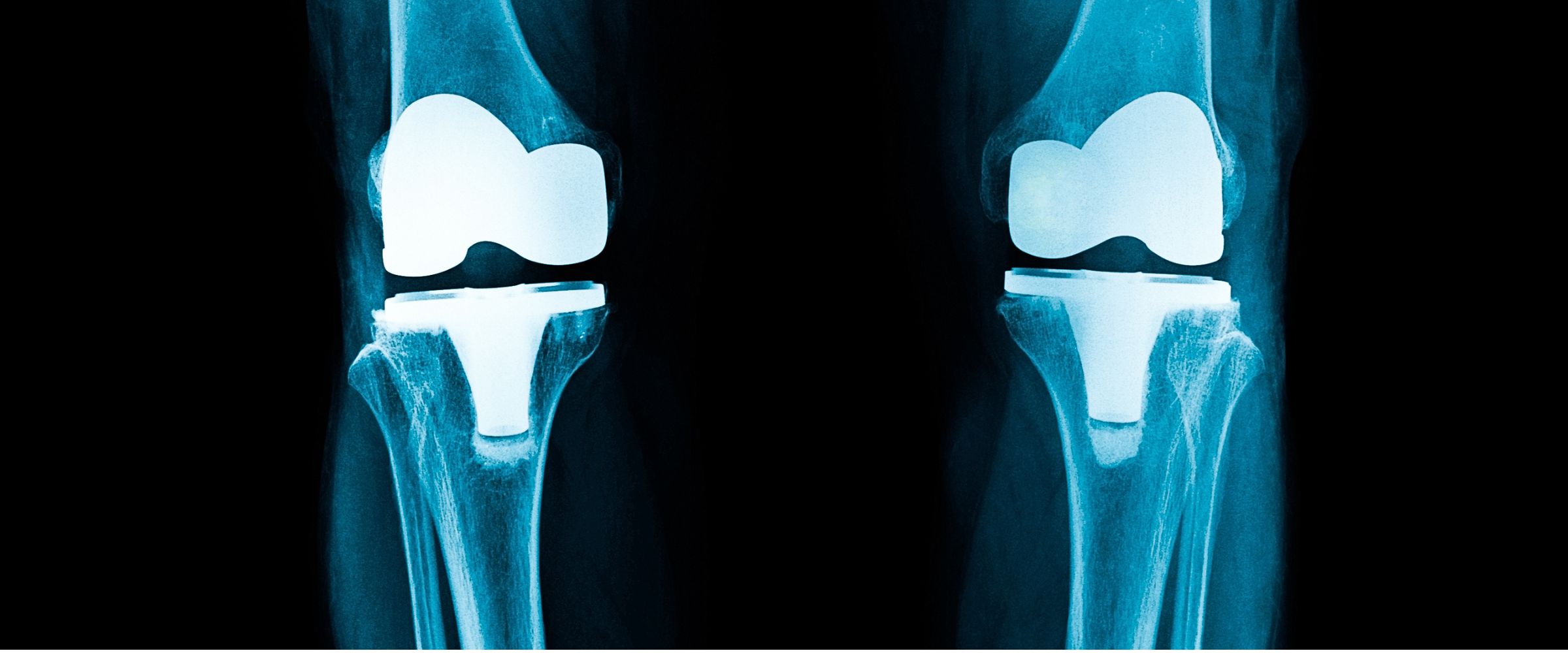

We'll help you meet your medical implant cleanliness specs.

Eliminate burrs, defects, and other surface finish issues

A medical implant company produced cleaner parts while achieving cutting time reduction of 67% and longer tool life.

We understand the challenges of investing in new technology in the medical machining space, which is why we have a no-upfront-capital-required option. We're so confident that Pure-Cut will deliver powerful manufacturing improvements for your plastic medical implant production, our risk-free contracts will get you access to cutting-edge machining capabilities without the capital hurdle.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.