Significant Machining Capacity and Expansive Research Facility

Fusion Coolant Systems helps companies looking for a cleaner, safer and more productive alternative to traditional cutting fluids.

Fusion Coolant Systems helps companies looking for a cleaner, safer and more productive alternative to traditional cutting fluids.

Fusion Coolant Systems serves some of the largest automotive, aerospace and medical device manufacturers around the world with sustainable solutions for advanced cooling and lubrication. A newly expanded Customer Center in Canton, MI supports companies looking for a sustainable approach to traditional cutting fluids.

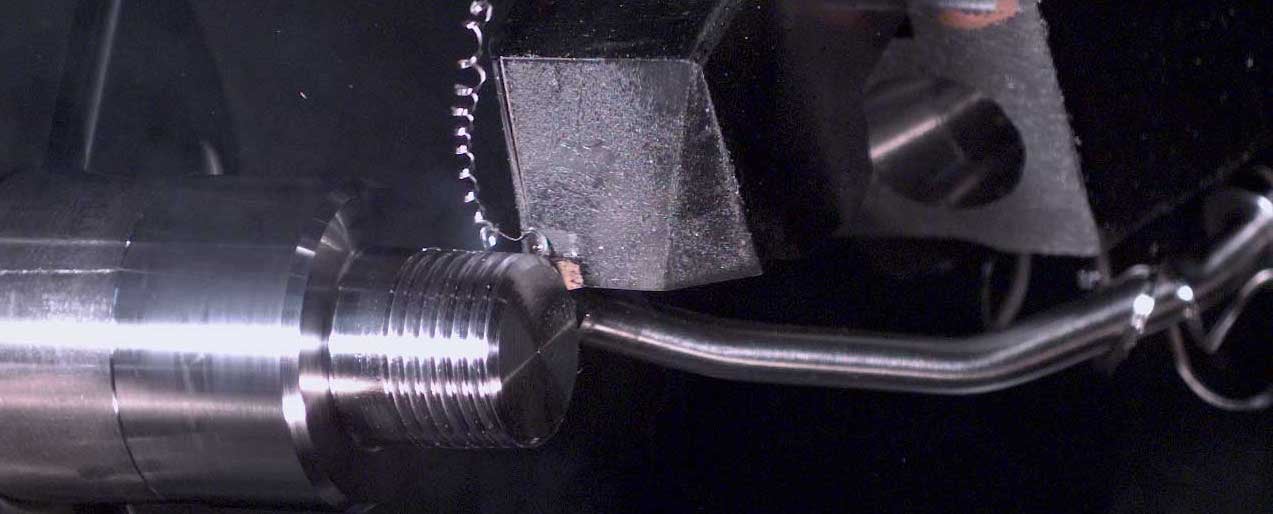

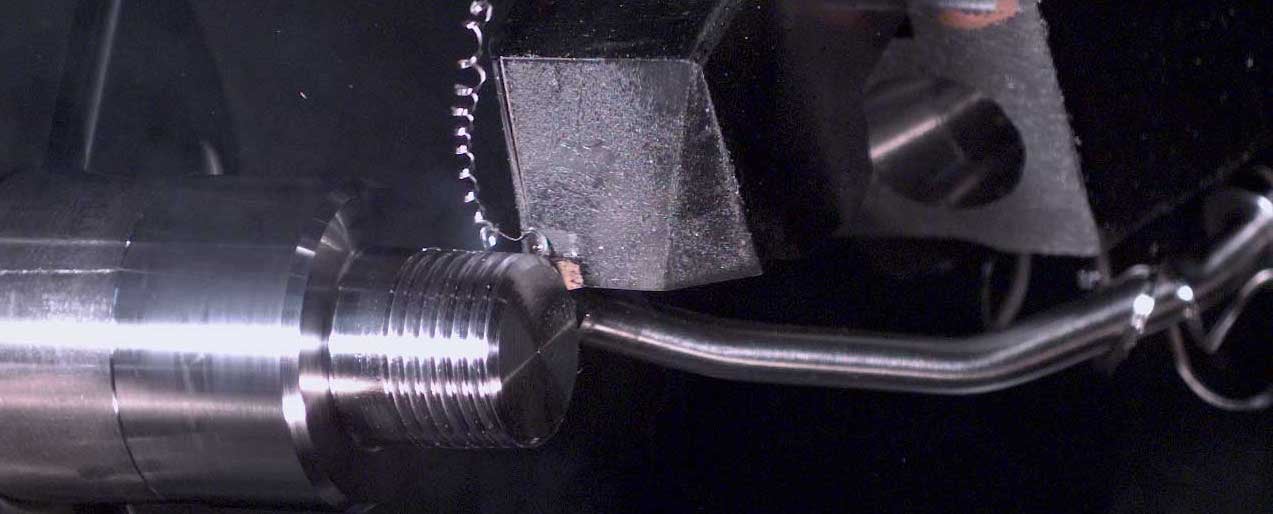

Showcasing CO2 infrastructure with recycled CO2 supporting Pure-Cut®.

Testing for specific use cases.

Exploring different materials and operations.

Allowing customers to see simple and seamless integration of Pure-Cut and Pure-Cut®+.

“The CO2 infrastructure we installed at our own facility is very similar to what our customers install at their sites. It allows customers coming through to see how easy it is to integrate into their operation and lets them see just how small the footprint really is.”

- Scott Jones, Director of Engineering.

In addition to a customer center, Fusion Coolant Systems headquarters maintains secure space for customer-specific data and tools.

The facility has fully integrated and advanced infrastructure in place that can handle up to 10 Pure-Cut systems with recycled CO2.

Customers can easily share the data and video of their parts being Pure-Cut with colleagues.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.