Transform your machining operations with the Pure-Cut® solution

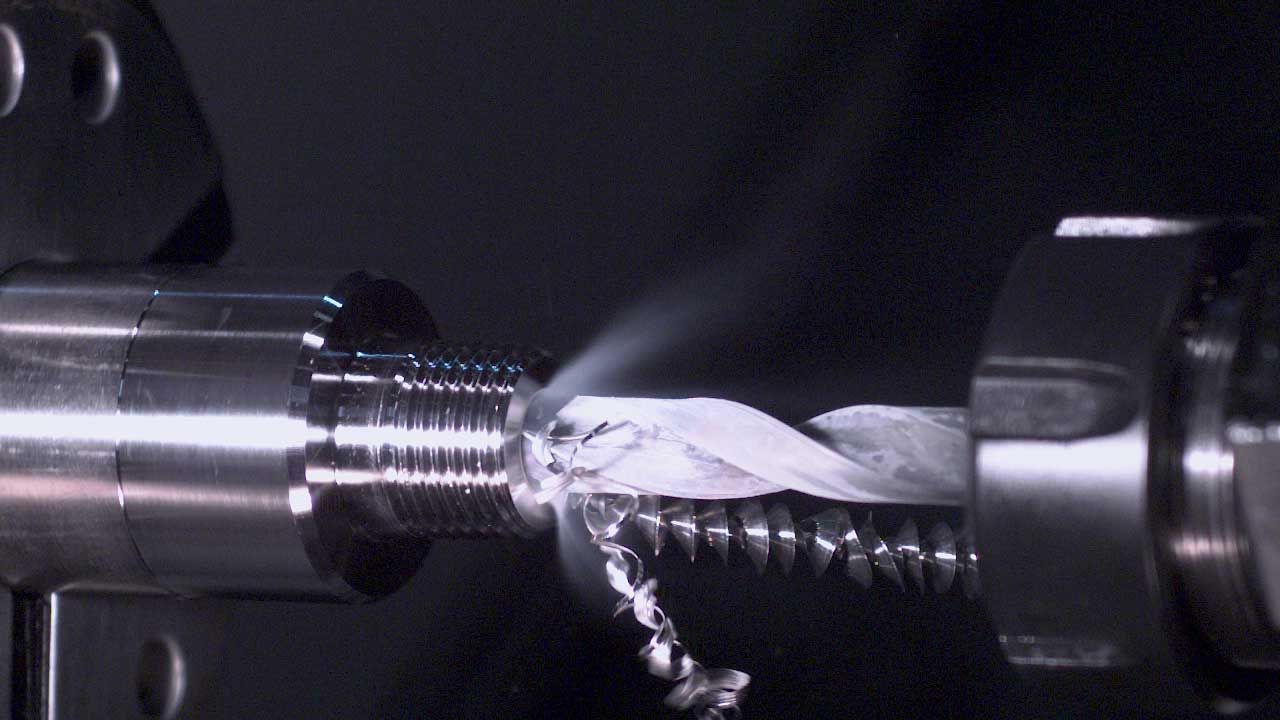

Our patented Pure-Cut® machining solution uses supercritical carbon dioxide (scCO2) to elevate your operations, providing many advantages over machining with conventional coolants and lubricants. Pure-Cut® is a non-toxic, non-flammable, and environmentally friendly solution that does not produce harmful waste. The scCO2 penetrates the cutting edge providing better cooling and lubrication, reducing tool wear and improving machining accuracy. Parts are virtually burr-free with exceptional surface finishes. In addition, scCO2 is an exceptional solvent, leaving parts super clean, eliminating post-machining cleaning operations.

Read more about how Pure-Cut® can help your business.

3/23/2023

Micro-drilling is an excellent application for Pure-Cut® technology. scCO2 provides outstanding cooling and lubrication in this application. Research at the Institute of Precision Machining found that supercritical carbon dioxide can increase productivity, extend tool life, and lower costs.

8/30/2022

Advanced machining systems with robotics and vision systems need to be able to "see" into the machining center to accurately move and position material. Pure-Cut® technology utilizing supercritical carbon dioxide is the optimal solution for these applications. scCO2 provides a clean, dry environment for the sensors to work quickly and effectively.

8/24/2022

The Pure-Cut® solution utilizing supercritical carbon dioxide provides longer tool life, clean operation, and enhanced employee health and safety benefits. If it is necessary to switch back to emulsion based cooling and lubrication, it can happen in a matter of seconds - watch the real-time video to see it in action.

8/1/2022

As medical devices become more complicated, precision CNC machining provides a cost-effective way of manufacturing these pieces. The Pure-Cut® cutting solution from Fusion Coolant Systems allows manufacturers to deliver highly precise, medically clean products with outstanding surface quality, free from burrs and imperfections.

7/27/2022

Supercritical CO2 is the next level in CNC machining solutions. The patented Pure-Cut® solution can extend tool life while at the same time increasing feeds and speeds, improving productivity, reducing costs, and minimizing out-of-spec parts. Take the next step in machining technology with Fusion Coolant Systems.

7/7/2022

Reducing your environmental footprint can have a major impact on your business. In the machining industry there are many processes that impact air and water quality through the process waste streams. Pure-Cut® machining solutions help to minimize the impact to our environment. Using recovered and recycled carbon dioxide you can reduce your reliance on oil based lubricants and emulsion coolants, minimizing or even eliminating hazardous waste from your process.

6/30/2022

Dr. Steve Skerlos, professor at the University of Michigan and founder of Fusion Coolant Systems, talks about how the supercritical carbon dioxide technology is changing the world of machining. Faster feeds and speeds, longer tool life, and improved employee health and safety are just a few of the benefits from Pure-Cut® technology.

6/23/2002

There are many factors that affect tool life in CNC machining operations. One critical component is the type of cooling and lubrication used in the process. The Pure-Cut® solution using supercritical carbon dioxide has been proven to extend tool life significantly. In cast iron you can double speeds and feeds and extend tool life by up to four times.

6/21/2022

Extending the life of tools for CNC machining is an ongoing challenge for manufacturers. A dull or broken tool slows production and adds cost to the product. Pure-Cut® solutions using supercritical carbon dioxide was shown to extend tool life by 2X over emulsion when cutting Ti-64.

5/24/2022

Machining metal produces chips, tons of them. These chips are valuable to a company when they can be recycled. However, dirty, wet chips have a lower value than clean, dry chips. The Pure-Cut® solution using supercritical carbon dioxide produces a naturally clean chip that doesn't require post-processing. Get the maximum value for your scrap with Pure-Cut® from Fusion Coolant Systems.

5/19/2022

Machining metal is an important part of the manufacturing process, and CNC machines perform that task efficiently and safely, but they are also a leading cause of fires in manufacturing facilities. Many of these fires are caused by the oil-based lubrication systems used to cool the tooling in the machines. Supercritical carbon dioxide used in the Pure-Cut solution acts as both a fire suppressant and a lubricant in your machining process. Learn more here.

5/17/2022

Micromilling with CNC machines is complex and challenging but the Pure-Cut® technology from Fusion Coolant Systems is a game-changer for the industry. Research published in the Journal of Manufacturing Science and Engineering demonstrated that in the micromilling of copper 101 and type 304 stainless steel, Pure-Cut® reduces specific cutting energy, burr formation, and surface roughness – in addition to reducing tool wear – under high feed conditions. Learn more about how we can improve your micromilling operation.

5/12/2002

Increases in production and new business opportunities challenge machine shops daily. Floor space is at a premium, and adding a new machine can be difficult. Pure-Cut® solutions from Fusion Coolant Solutions can reduce your machine tool footprint by eliminating the need for traditional emulsion cooling systems and the associated equipment. Save space and increase your profitability with supercritical carbon dioxide and the Pure-Cut® solution.

5/5/2022

Utilizing recovered and recycled carbon dioxide, the Pure-Cut® solution from Fusion Coolant Systems helps to reduce the variable cost of machining a part by eliminating the costs associated with conventional emulsion cooling and lubrication. Additional savings can be achieved by tool life extension, faster speeds, cleanliness, and elimination of deburring - all part of the Pure-Cut® solution.

4/28/2022

Eliminate hand-deburring of parts machined in UHMWPE by using Pure-Cut® cutting solutions from Fusion Coolant Systems. Researchers at the Institute of Precision Machining (KSF) have shown the success of using supercritical carbon dioxide to machine this challenging material. Watch their video of Pure-Cut® technology in action and see how the results point towards a higher material removal rate, significant reduction in burrs, improved work-piece accuracies, and better surface quality.

4/14/2022

Waste reduction in the CNC machining process is a key component of implementing lean manufacturing techniques in your facility. One area of excess waste is machining coolant. Pure-Cut® machining solutions utilize recovered carbon dioxide to increase feeds and speeds, and eliminate a waste stream in your facility.

4/12/2022

The Pure-Cut® cutting solution using supercritical carbon dioxide (scCO2) has been shown to improve material removal rates in CNC machining operations. Learn more about cutting standards and how to increase production and lower costs.

4/8/2022

Research by the Nuclear AMRC Advanced Manufacturing Research Center in Sheffield UK found that using supercritical CO2 for machining AISI 304L stainless steel increased tool life by over 300% and decreased surface roughness by 30% compared to flood coolant. Read more about how the Pure-Cut® machining solution can improve your operation.

3/31/2022

Manufacturing engineers looking for an advantage know how a lights-out strategy can benefit them. However machining with oil can pose a significant fire hazard in unattended operation. With Pure-Cut®, supercritical carbon dioxide delivers dry and enhanced lubrication to a cutting zone for applications demanding high lubrication and high cooling, with much faster material removal and longer tool life - with no fire risk.

3/29/2022

Researchers from Technische Universitat Braunschweig showed in a 2021 paper that Pure-Cut® can reduce forces and cutting power while using less energy in surface grinding. If you are looking to increase tool life in manufacturing, read more to see how the Pure-Cut® solution can help reduce tool wear.

3/24/2022

For health and safety in machining plants, NIOSH recommends that exposures to MWF aerosols be limited to 0.4 milligrams per cubic meter of air (thoracic particulate mass) or 0.5 milligrams per cubic meter of air (total particulate mass), as a time-weighted average concentration up to 10 hours per day during a 40-hour workweek. Maximum oil flow for Pure-Cut is 50mL per hour, easily achieving this recommendation! Learn how the Pure-Cut® solution can help you meet employee health and safety standards.

3/17/2022

In the turning of medium carbon steel, researchers at Advanced Machining Research Group at the Universiti Tun Hussein Onn Malaysia demonstrated that compared with MQL, Pure-Cut® can reduce cutting forces by 15%, cutting temperature by 30%, and specific cutting energy by 10% enabling faster machining speeds and longer tool life. Read what the Pure-Cut® solution can do for your operation.

Developed through extensive research, Pure-Cut® and Pure-Cut®+ bring the patented process of cooling and lubrication with supercritical carbon dioxide to applications around the world.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.