Supercritical carbon dioxide, inherently a superior lubricant, provides oil-quality lubrication without the waste or health risks. Higher cooling and high lubricity with higher pressure lead to higher productivity – improving chip evacuation, lowering operational costs, and improving environmental, health, and safety impacts.

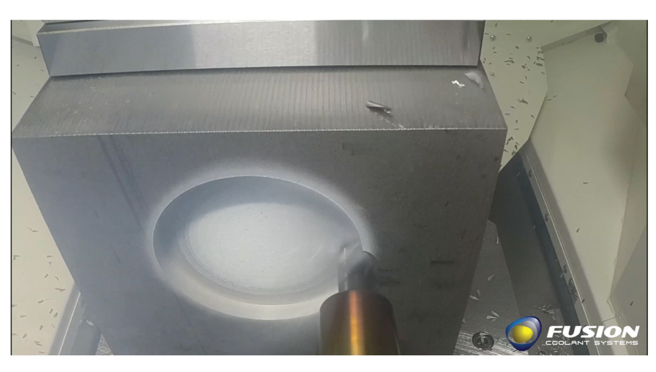

Achieve a more precise surface finish.

Drastically extend tool life and avoid downtime.

Reduce carbon footprint by using waste CO2, using fewer tools, and having faster speeds.

Eliminate exposure to harmful metalworking fluid chemicals.

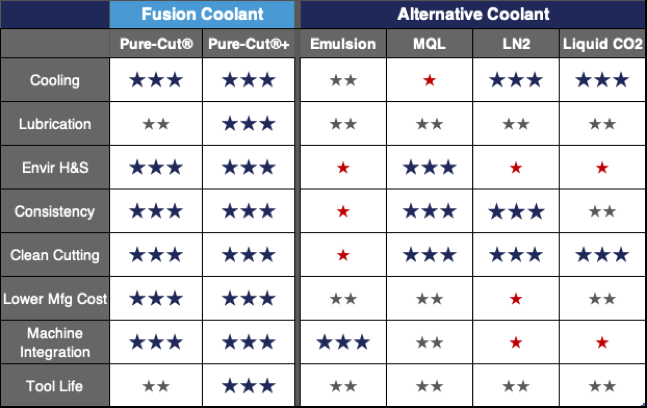

Pure-Cut® and Pure-Cut®+ bring previously unattainable advanced cooling and lubrication to applications that can benefit from quick, consistent, clean solutions. The patented technology extends tool life, decreases cycle time, and achieves more precise surface finishes without facing the same challenges as traditional materials:

Dirty parts and slower cutting cause sustainability, health, and safety concerns

Unable to cool effectively

Too cold and unable to lubricate

Poor lubrication, inconsistent and requires major overhaul to machine tools

Pure-Cut+ customers achieve at least 30% performance improvements – allowing them to cut faster and ultimately get to market more quickly.

Pure-Cut achieves highly precise finishes, allowing users to confidently deliver superior quality products.

Massive speed improvements compared to traditional cutting fluids and cryogenics.

Precise surface finish when micron-level differences matter.

Tools last significantly longer than with traditional lubricant in most materials.

Lower carbon footprint and eliminate worker exposure to fluid chemicals.

Easy to integrate into current machine tools. Easy to revert to traditional cutting fluids, if desired.

Efficient operation and decreased maintenance.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.