Pure-Cut® advanced cooling and lubricant solutions are designed for clean machining of precision-critical components that go in the air, on the road, or inside the human body. Our solutions provide cooling and lubricant for any metals, from aluminum to Inconel – on any CNC operation where there is a cutting surface that needs to be cooled and lubricated.

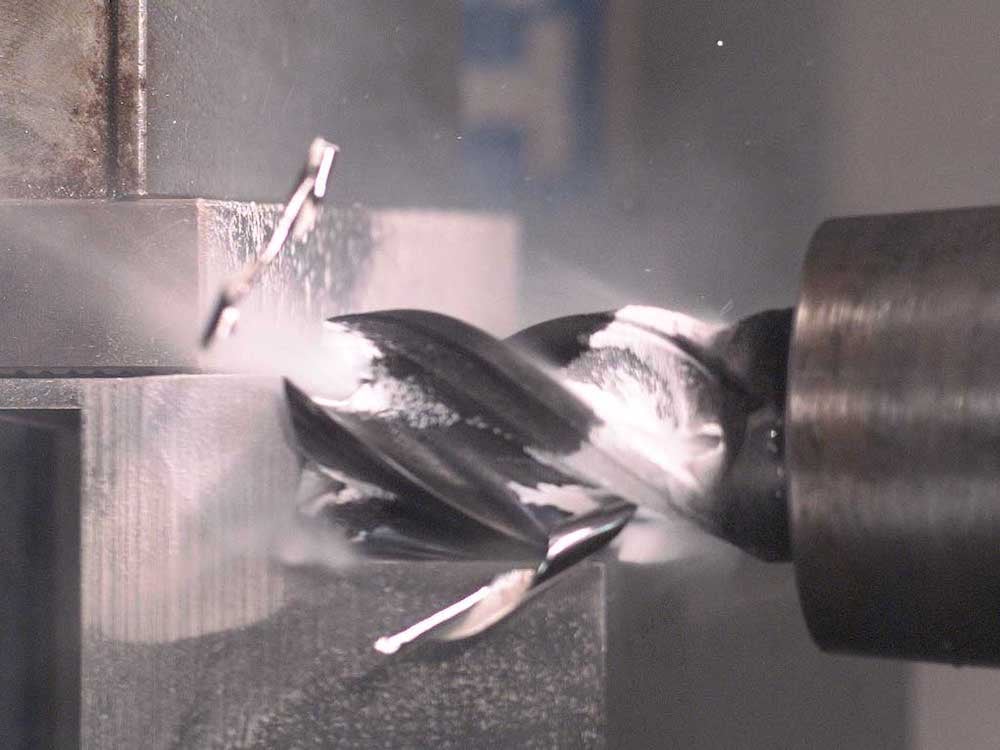

More efficient cutting of titanium, Inconel, and other heat recalcitrant materials.

Use Pure-Cut or Pure-Cut+ to increase productivity.

Decrease cycle time and lengthen tool life.

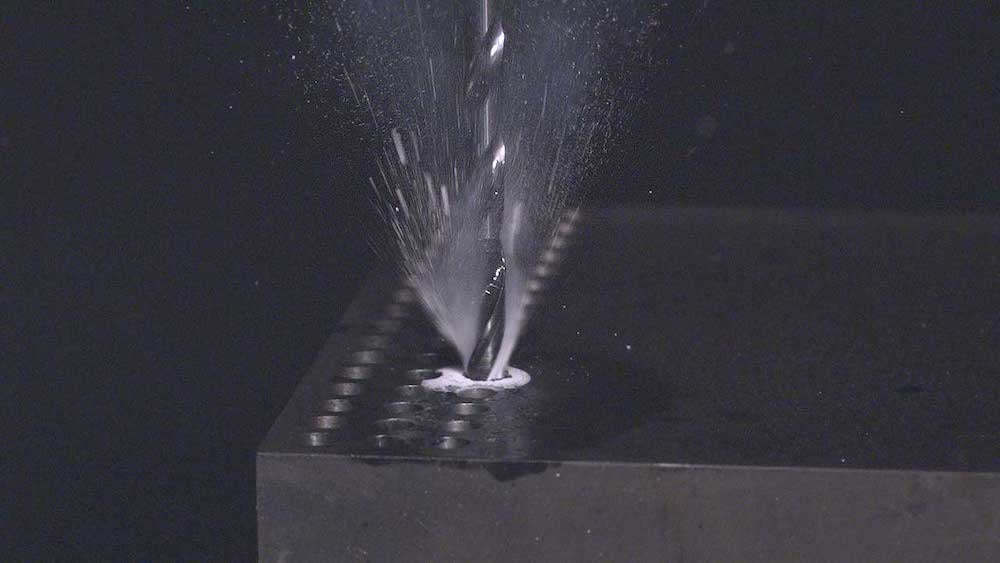

Fusion helped develop a through-tool cutting process with 0.080mm-0.100mm diameter coolant holes.

Fusion delivered lubrication more efficiently with supercritical carbon dioxide and significantly lowered cutting forces while reducing heat.

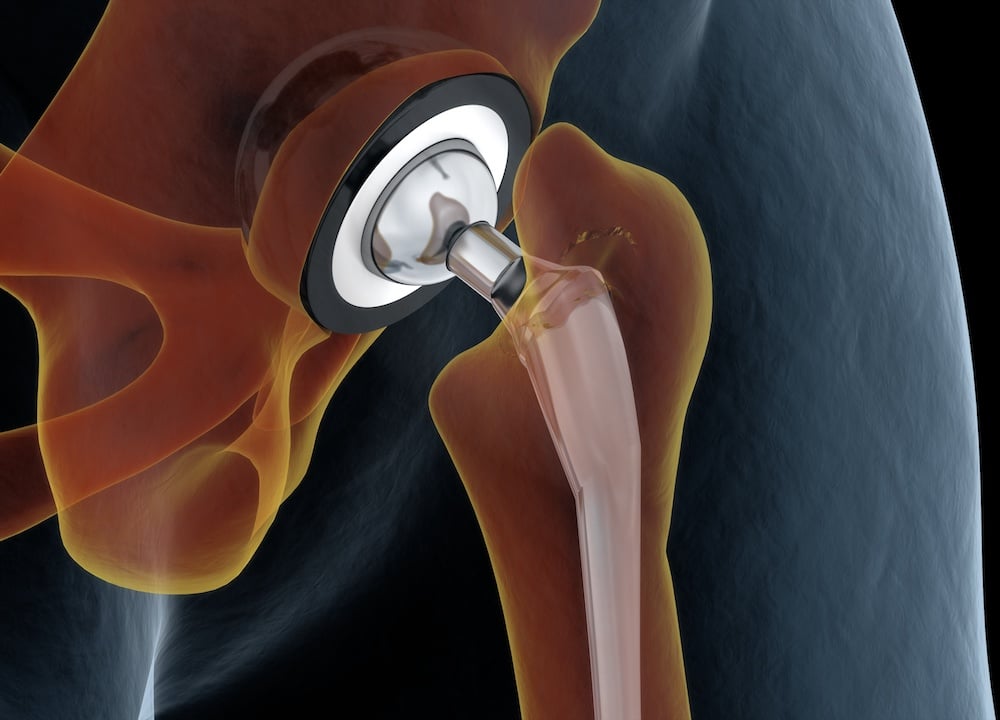

A medical implant company could differentiate their production with faster feed rates and clean parts, while maintaining or improving tool life.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.