Manufacturers often face challenges such as high cutting temperatures, burr formation, and extended cycle times when machining PEEK. With Pure-Cut®, we guarantee significant improvements in the CNC machining metrics that matter most.

Achieve pure, contaminant-free machining with superior machining cleanliness compared to traditional flood coolants.

We'll help you meet your specific cleanliness specifications for PEEK components.

Eliminate burrs, defects, and other surface finish issues effectively.

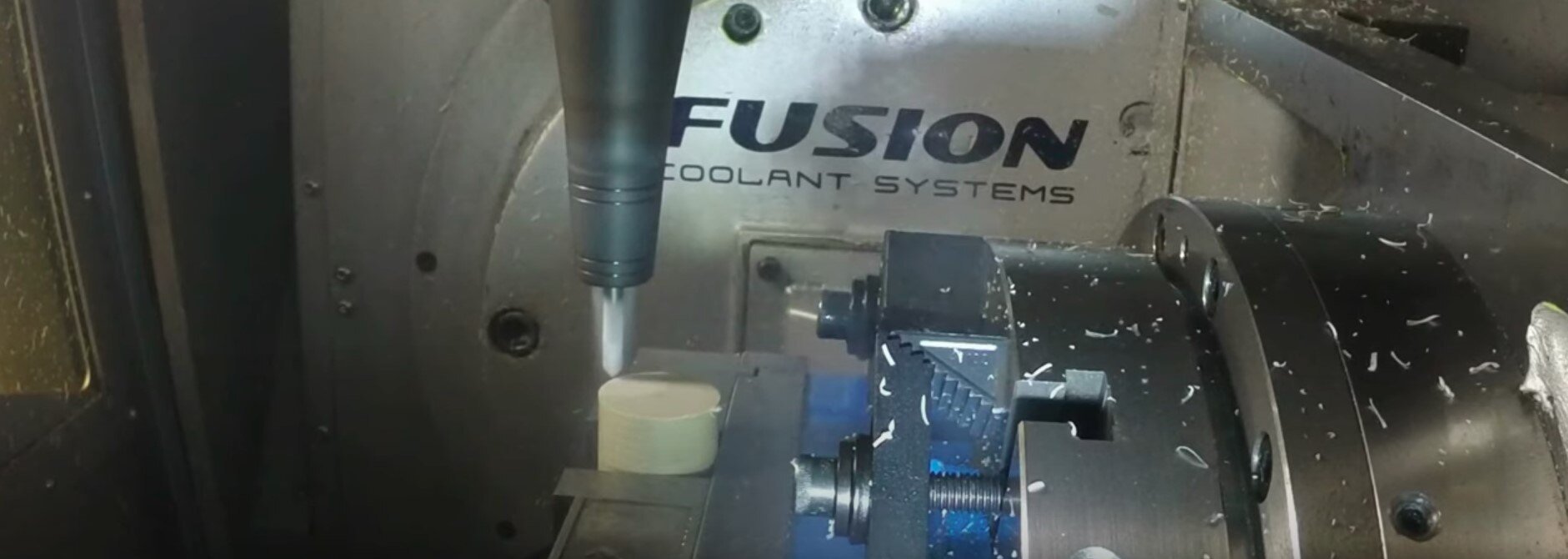

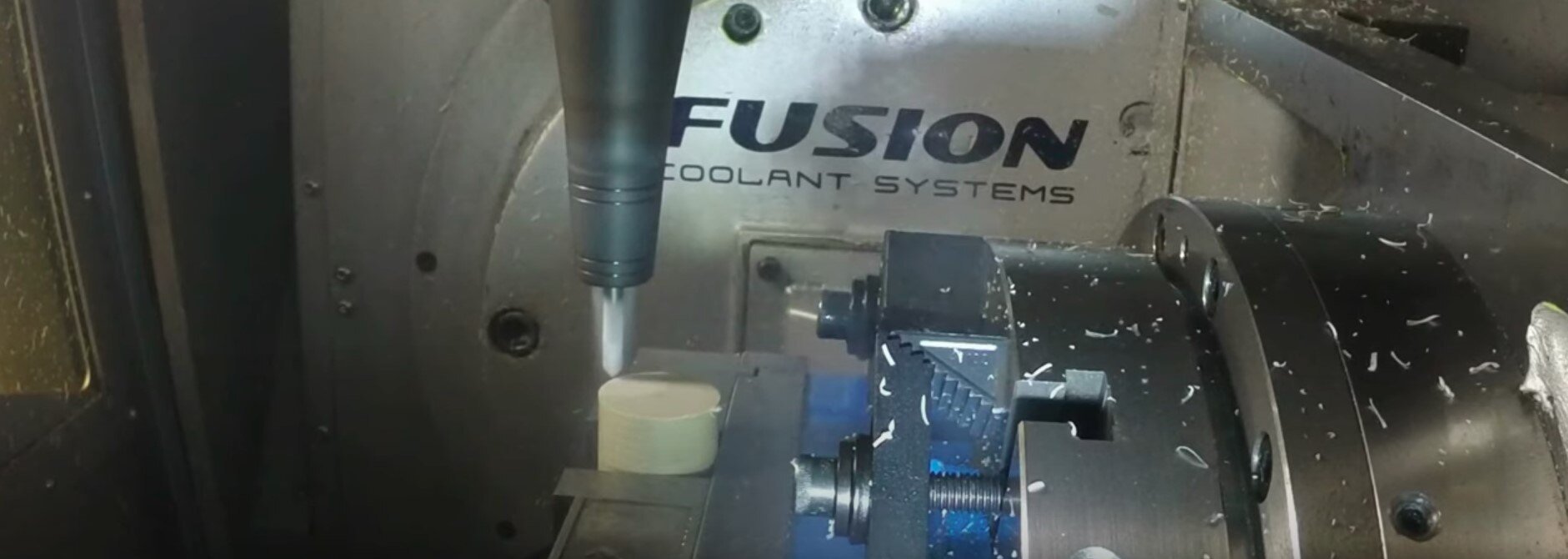

Pure-Cut® technology brings unmatched precision to PEEK machining. With supercritical CO₂ as its cooling agent, Pure-Cut® minimizes burr formation, achieves superior dimensional accuracy, and reduces cycle times by up to 60%, making it the leading choice for manufacturers who prioritize quality and efficiency. Say goodbye to costly rework and subpar finishes—Pure-Cut® ensures optimal results every time.

We recognize that investing in new technology for PEEK machining can be daunting, which is why we offer a no-upfront-capital-required option. With our risk-free contracts, you can access cutting-edge machining capabilities without financial constraints, ensuring you stay competitive in the market.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.