Different from cryogenics or liquid nitrogen, supercritical carbon dioxide brings unprecedented sustainability and efficiency to CNC machining.

Decrease Cycle Time, Improve Cut Quality, and Extend Tool Life with supercritical CO₂

Supercritical CO2 inherently provides lubrication effects that match those of traditional cutting fluids. A simple solution for lubrication and cooling, supercritical CO2 is a fluid state of CO2 held above its critical temperature and critical pressure. At this point, the CO2 looks like a gas, but has the density of a liquid – providing powerful cooling and lubrication for machine tools with minimal integration challenges for your manufacturing facility. Supercritical CO2 can also carry and disperse chilled nanodroplets of oil for even more powerful lubrication.

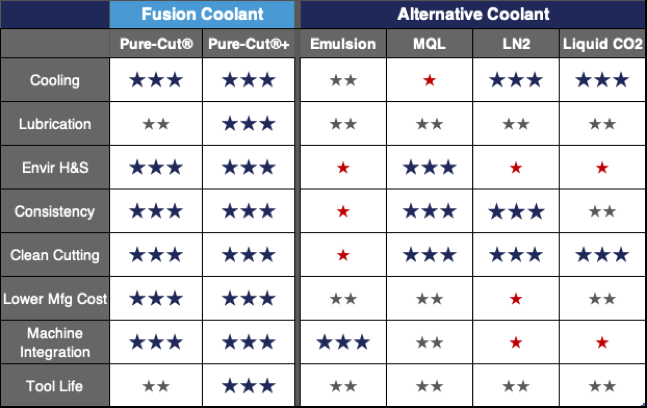

Pure-Cut® and Pure-Cut®+ were designed to use supercritical CO2 for cooling, lubrication, and advanced chip removal. Pure-Cut and Pure-Cut+ do not overhaul machine tools like cryogenic or liquid nitrogen coolants. Instead, they work with existing machine tools, delivering CO2 in it's supercritical state into the cutting process and providing advanced coolant and minimal quantity lubricant if needed.

Massive speed improvements compared to traditional cutting fluids and cryogenics.

Precise surface finish when micron-level differences matter.

Tools last significantly longer than with traditional lubricant in most materials.

Lower carbon footprint and eliminate worker exposure to fluid chemicals.

Easy to integrate into current machine tools. Easy to revert to traditional cutting fluids, if desired.

Efficient operation and decreased maintenance.

Pure-Cut® uses only supercritical CO2 for dry machining, ideal for applications such as the medical industry where 100% clean environments and precise surfaces are absolutely critical.

Supercritical CO2 used for Pure-Cut and Pure-Cut+ comes from recycled sources, both saving cost and decreasing your carbon footprint.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.