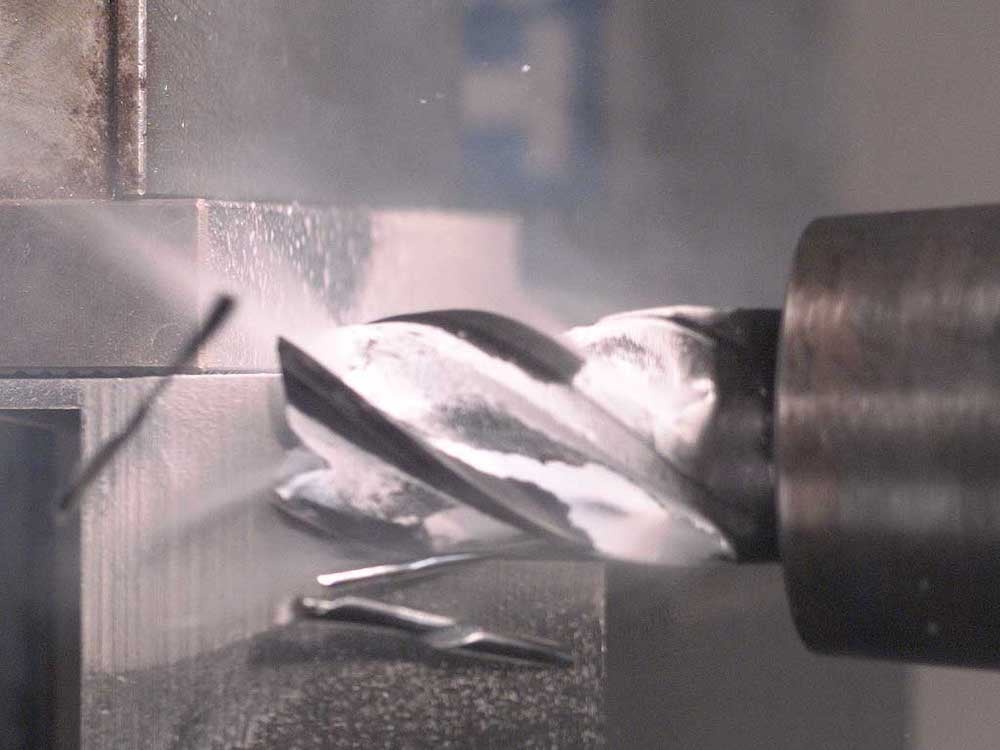

The supercritical carbon dioxide at the core of Pure-Cut® and Pure-Cut®+ solutions brings the sustainability in manufacturing and EH&S results that competitive organizations need in machine cutting applications. With Pure-Cut and Pure-Cut+, organizations can lower the carbon footprint of machine tooling systems and benefit from a chip evacuation process eliminates health and safety risks associated with traditional systems.

Eliminate machining induced risks of dermatitis, hypersensitivity pneumonitis, various cancers and many other health problems.

Eliminate water pollution from machining, reduce dependence on oil.

Utilizes recovered CO2 as a resource.

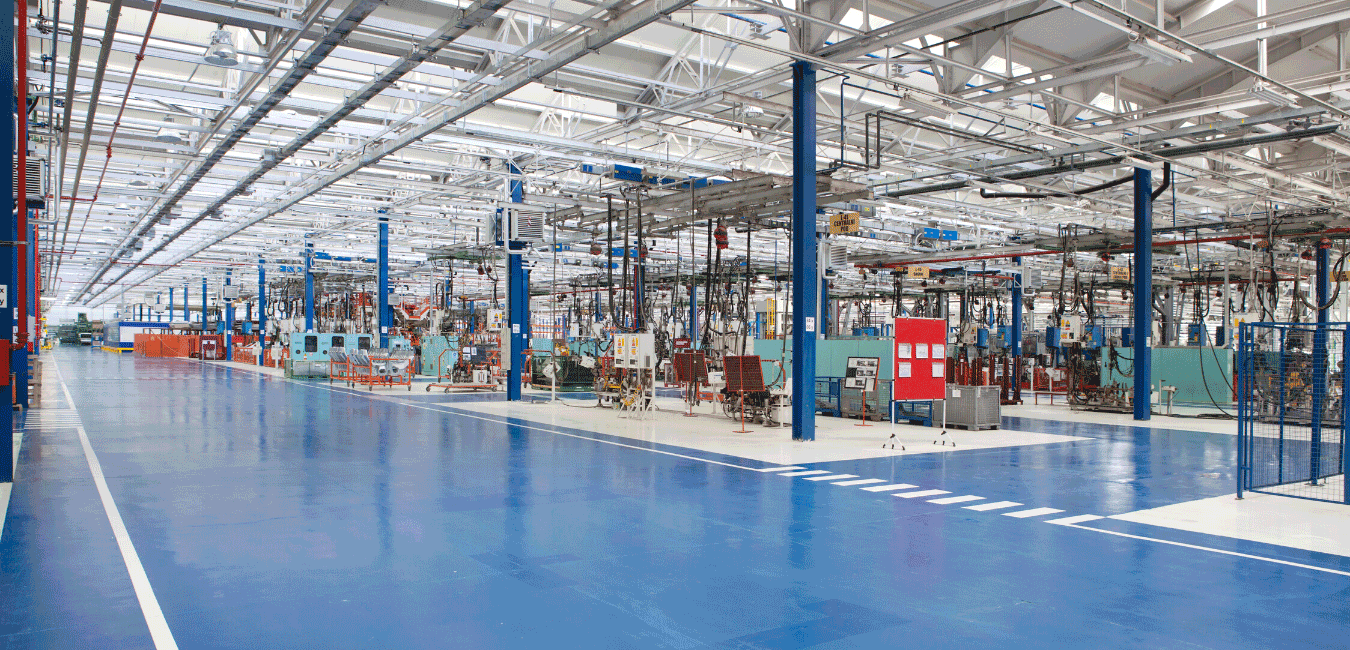

Support and create more productive, safer machining around the world, improving sustainability in manufacturing.

Traditional cutting fluids create hazards for the environment and for workers. At Fusion Coolant Systems, we created an environmentally friendly replacement for cooling and lubrication that inherently performs better, too. It is our goal to improve sustainability in manufacturing with this revolutionary solution.

We’re helping manufacturers ensure workers no longer breathe, handle, or interact with inherently contaminated fluids carrying heavy microbial and chemical risks:

Eliminate worker exposure to common metalworking fluid chemicals such as biocides, defoamers, chelating agents, and surfactants.

Use the optional lubricant that suits your application and workers best – from vegetable oil to synthetic ester to other worker-compatible lubricants.

Remove the concerns of respiratory conditions and dermatologic issues NIOSH most commonly associated with exposure to traditional metalworking fluids.

CO2 is inherently clean and used around the world as a cleaning fluid for difficult liquids in diverse applications ranging from semi-conductor fabrication to heavy equipment manufacturing. It has also won several presidential green chemistry awards, improving sustainability in manufacturing. Pure-Cut and Pure-Cut+ use CO2 as a lubricant for advanced cooling and lubrication:

The path toward a more sustainable solution without sacrificing quality starts now, with your machine tools:

Reuse CO2 from other applications, purchased from a gas supplier as recovered CO2 from exhaust smokestacks of industrial operations.

Use recovered CO2 rather than using additional electricity to produce liquid nitrogen, pump water for aqueous metalworking fluids, or power inefficient shop air systems for air-in-oil lubrication.

Precise and flexible enough to use only the exact lubricants needed, at lower rates than even today’s oil-in-air technology. Also reduces tool consumption and increases machine tool utilization and efficiency.

Fusion Coolant Systems Pure-Cut® and Pure-Cut®+ technology uses supercritical CO2 as an advanced coolant and lubrication on CNC machines. Pure-Cut delivers a sustainable solution with incredible performance benefits, while minimizing EH&S risks associated with traditional cutting fluids.